1 Nov. 2023: For almost 20 years, Swedish software company FrontWay has provided an economical, simple and highly useful simulation tool to increase mill energy efficiency, increase product quality and boost process performance. The software tool is called PaperFront® and is used daily by the largest companies.

PaperFront® is a material and energy-oriented block-based simulation software developed for complete production-analysis with a focus on the pulp- and paper industry.

PaperFront® provides dynamic and steady state simulations with material, energy and quality evaluation and prediction. It is possible to simulate components like energy, steam and moisture, chemical components, solids and solubles. It also manages quality characteristics such as stiffness, brightness and more.

Energy savings and optimisation with PaperFront®

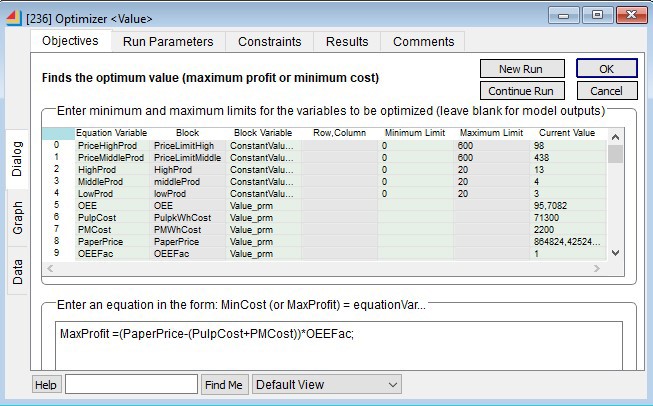

Simulations teach you how to best use your equipment and processes. PaperFront® includes an optimisation tool that you can apply to your models by defining variables, constraints and your objective function and the software will find a solution for you.

Example - Simulation can provide new information to boost efficiency in moisture measurement

Measuring moisture at an early stage can reduce energy usage and improve runnability. Dryer steam use constitutes up to 80% of the energy used in paper making and a 1% reduction in moisture before the sheet enters the Drying Section can reduce energy consumption in the Dryer Section by some 4%.

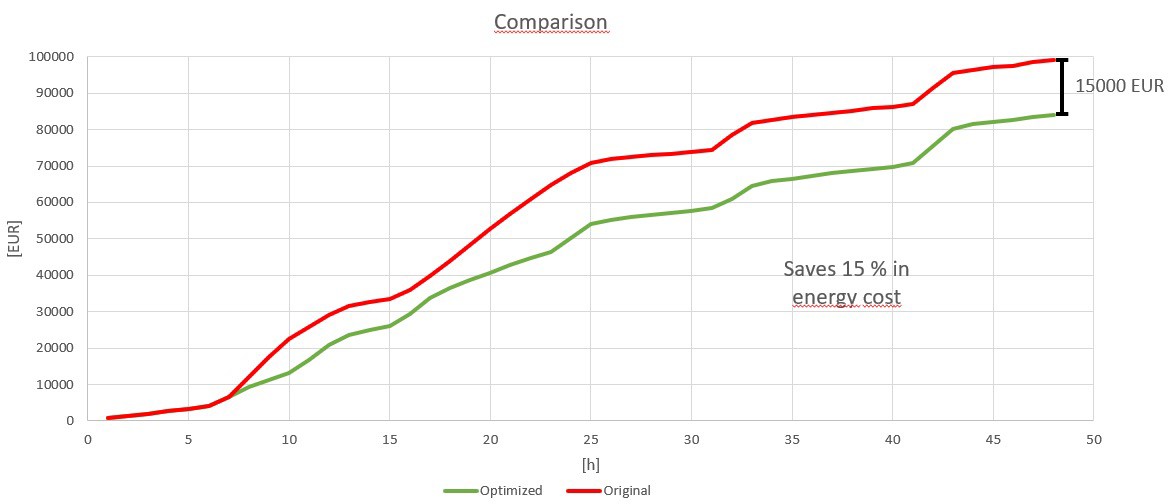

In the image you can see a picture of the optimisation dialogue. In this example, the optimiser decides when to speed up the pulp production and when to slow it down depending on the available energy type and price. The results of this evaluation serve as a guide for the operation of the mill for the next 42 hours.

PaperFront® is developed by FrontWay AB with 20 years in the business.

Our main customers are machine vendors, chemical suppliers, mills and consultancy. Beside software development we also provide consultant services.

Consultant services

- Design data for new construction or rebuilds

- In depth simulation/prediction of quality parameters

- Energy studies and savings

- Pinch data analysis

- Environmental impact studies

- Production planning and optimisation

- Programming services

- Training in simulation

Simulation package

PaperFront® handles all simulation and prediction issues you may have

- Designed for Pulp and paper mills

- Dynamic and steady state simulations

- Material, energy and quality evaluation and predictions

- Evaluation of scenarios

- Production planning in the mill

- Supports import and connection to DCS

Some references

FrontWay is a major player in the development and use of simulation software in Europe for the pulp and paper industry. FrontWay can deliver throughout the mill, from raw material reception to finished product. There are no limitations in terms of components, energy or chemical reactions. We have built models and developed solutions for pulp, TMP, recycled paper, board machines, paper machines and tissue.

Among the many satisfied customers are Valmet, Voith and Kadant.